- { Create }

- Wire

- Sheet

- Tools

- DVDs

- Streaming Video

-

Beads

- Handmade Venetian Glass Beads

-

Shop by Gemstone

- Agate - Blue Crazy Lace

- Agate - Blue Lace

- Agate - New Brazilian

- Agate - Pink Crazy Lace

- Agate - Purple Crazy Lace

- Agate - Rainforest

- Agate - Turritella

- Amethyst

- Amethyst - Dog Teeth

- Apatite - Blue

- Bronzite

- Carnelian

- Carnelian - Matte

- Cat's Eye

- Chrysocolla

- Dumortierite

- Dumortierite - Purple

- Goldstone - Blue

- Goldstone - Brown

- Goldstone - Green

- Hematite

- Jade

- Jade - New Burma

- Jade - West African

- Jade - Yellow

- Jasper - Apple

- Jasper - Black Silver Leaf

- Jasper - Dragons Blood

- Jasper - Green Brecciated

- Jasper - Imperial

- Jasper - Iron Zebra

- Jasper - Mexican Red Snowflake

- Jasper - Noreena

- Jasper - Picasso

- Jasper - Picture

- Jasper - Porcelain

- Jasper - Red Creek

- Jasper - Red Creek - Matte

- Jasper - Red Porcelain

- Jasper - Venus

- Jasper - White Lace Red

- Jasper - Wildhorse

- Labradorite

- Lapis

- Malachite

- Obsidian - Golden

- Obsidian - Snowflake

- Onyx

- Onyx - Matte

- Orange Sodalite

- Prehnite

- Pyrite

- Quartz - Blue Green

- Quartz - Cherry

- Quartz - Rose

- Quartz - Smoky

- Rhyolite

- Rhyolite - Bird's Eye

- Sardonyx

- Seraphinite

- Sodalite

- Tiger Eye

- Tiger Eye - Blue

- Tiger Eye - Red

- Turquoise - African

- Turquoise - Yellow

- Pearls

- Swarovski Crystal Beads

- Stones & Supplies

- On Sale Now

Home

/ Jewelry Making Articles

/ American Wire Gauge

American Wire Gauge

by Judy Ellis

How is wire gauged? Since 1857, the United States has been using a standard system in measuring the diameter of wire. This system is known as American Wire Gauge (AWG), or the Brown & Sharp (B&S) gauge, and was invented by J.R. Brown.

A customary wire gauge is circular or rectangular in shape with grooves along the outside. The size of the grooves represents the diameter of the wire. The higher the gauge number, the smaller the diameter and finer the wire. The lower the gauge number, the bigger the diameter and thicker the wire. When wire is manufactured, thick wire is progressively stretched to thinner and thinner wire, until the desired gauge is achieved. This process is recognized as wire drawing or die casting. The wire is pulled through one or more drawing dies (a metal mold consisting of larger to smaller holes) to acquire a number gauge. The wire gauge measurement refers to the number of dies that the wire had to be pulled through to achieve the specific diameter. In other words, higher gauge wires are pulled through more dies than the lower gauge wires.

AWG measurements can be found from a 000000 gauge, which is ¬about a half an inch in diameter, down to a 40 gauge, which is equivalent to 0.00314 inches or .07986 millimeters in diameter. Typical telephone wire is 22, 24, or 26 gauge, household wiring is 12 or 14, and electronic wiring is commonly a 20 gauge. In the AWG system, when the measurement of the gauge decreases by six, the diameter of the wire doubles. For instance, a 24 gauge wire is about .02" in diameter, an 18 gauge wire is about .04" in diameter, and a 12 gauge wire is about .08" in diameter.

AWG measurements can be found from a 000000 gauge, which is ¬about a half an inch in diameter, down to a 40 gauge, which is equivalent to 0.00314 inches or .07986 millimeters in diameter. Typical telephone wire is 22, 24, or 26 gauge, household wiring is 12 or 14, and electronic wiring is commonly a 20 gauge. In the AWG system, when the measurement of the gauge decreases by six, the diameter of the wire doubles. For instance, a 24 gauge wire is about .02" in diameter, an 18 gauge wire is about .04" in diameter, and a 12 gauge wire is about .08" in diameter.

Note: Great Britain and Canada do not use the AWG; they use what is known as the Imperial or British Standard Wire Gauge (SWG or BSG). Under the SWG system, the thickest wire is 7/0 gauge, which is about 12.7mm and the thinnest is 50 gauge, which is equivalent to 25 µm. Just to give an example of the difference between AWG and SWG, wire gauged at 1 in AWG has a diameter of 0.28997 inches; in SWG its diameter is 0.3 inches."

Materials

Wire

Shop Now

Add All Items to Cart

Tools

Wire Gauge by Euro Tool

GAU-144.10

- GAU-144.10

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $13.97

- Gold Club Price: $10.48

Add to Bag

Wire Gauge for All Sizes of Wire- Pack of 1

G7-8

- G7-8

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $13.97

- Gold Club Price: $10.48

Add to Bag

Add All Items to Cart

Supply Detail

loading...

Change Metal:

This Article requires:

Purchase quantity:

Price: $

Gold Club Price: $

Purchase quantity:

Price: $

Gold Club Price: $

Add to Bag

- Category: General Education

- Technique(s): General Education

Other Articles by Judy Ellis

The premier place for all your jewelry making needs. The best in wire, tools, cabochons, gemstone beads and more. As well as a superior resource for educational support to help build your jewelry making skills and techniques.

Gem Profile- Moissanite

Gem Profile- Moissanite Birthstone Swarovski Colors

Birthstone Swarovski Colors Gem profile- Paua and Abalone

Gem profile- Paua and Abalone Tips for Tucson Shopping- Gem Show Secrets

Tips for Tucson Shopping- Gem Show Secrets About Jewelry Chain- About Ball Chain

About Jewelry Chain- About Ball Chain About Jewelry Chain- Snake Chain and Omega Chain

About Jewelry Chain- Snake Chain and Omega Chain About Jewelry Chain- Bar Chain and Peanut Chain

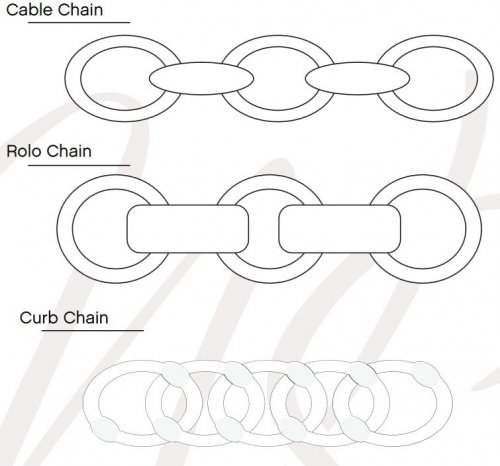

About Jewelry Chain- Bar Chain and Peanut Chain About Jewelry Chain- Cable Chain and Rolo Chain

About Jewelry Chain- Cable Chain and Rolo Chain About Jewelry Chain- Curb Chain and Gourmette Chain

About Jewelry Chain- Curb Chain and Gourmette Chain About Jewelry Chain- Figaro Chain

About Jewelry Chain- Figaro Chain About Jewelry Chain- Infinity Chain and Anchor Chain

About Jewelry Chain- Infinity Chain and Anchor Chain About Jewelry Chain- Chain Reference Sheet

About Jewelry Chain- Chain Reference Sheet About Jewelry Chain- Venetian Chain and Box Chain

About Jewelry Chain- Venetian Chain and Box Chain About Jewelry Chain- Wheat Chain and Rope Chain

About Jewelry Chain- Wheat Chain and Rope Chain Introduction to Chain

Introduction to Chain Access More Money by Making Jewelry When Your Prices Are Right

Access More Money by Making Jewelry When Your Prices Are Right An Introduction to Beads and Beading

An Introduction to Beads and Beading Common Gemstone Misconceptions

Common Gemstone Misconceptions Wire Wrapped Christmas Tree

Wire Wrapped Christmas Tree How To Polish Metal Jewelry using a Rotary Tumbler

How To Polish Metal Jewelry using a Rotary Tumbler How To Polish Your Own Rocks using a Rotary Rock Tumbler

How To Polish Your Own Rocks using a Rotary Rock Tumbler How to Merchandise Your Jewelry on the Internet

How to Merchandise Your Jewelry on the Internet How to Use Twitter as a Wire Jewelry Artist

How to Use Twitter as a Wire Jewelry Artist 20 Ideas to get your Jewelry Biz Busy

20 Ideas to get your Jewelry Biz Busy Watching the Precious Metals Market

Watching the Precious Metals Market Jewelry Design Ideas - Get Inspired

Jewelry Design Ideas - Get Inspired Measuring Tools

Measuring Tools July Birthstone - The Ruby

July Birthstone - The Ruby February Birthstone- Amethyst

February Birthstone- Amethyst March Birthstone - Aquamarine and Bloodstone

March Birthstone - Aquamarine and Bloodstone September Birthstone - Sapphire

September Birthstone - Sapphire November Birthstones - Topaz and Citrine

November Birthstones - Topaz and Citrine October Birthstones - Rose Zircon, Pink Tourmaline and Opal

October Birthstones - Rose Zircon, Pink Tourmaline and Opal April Birthstone - The Diamond

April Birthstone - The Diamond August Birthstone - Peridot and Sardonyx

August Birthstone - Peridot and Sardonyx June Birthstones - Alexandrite, Pearl and Moonstone

June Birthstones - Alexandrite, Pearl and Moonstone Metalsmithing

Metalsmithing Featured Tool - Mini TruStrike Hammers

Featured Tool - Mini TruStrike Hammers Natural Jasper Stones - Cabochon Gemstones

Natural Jasper Stones - Cabochon Gemstones Organize Your Jewelry Box

Organize Your Jewelry Box Pearls- It's a Cultural Thing

Pearls- It's a Cultural Thing Soldering 101

Soldering 101 Starting Your Own Home Jewelry Business

Starting Your Own Home Jewelry Business The Art of Creating Chainmail

The Art of Creating Chainmail Why Should I Be Using Facebook

Why Should I Be Using Facebook Make Handmade Neck Cords on a Dime

Make Handmade Neck Cords on a Dime Tagging Handmade Jewelry Gifts

Tagging Handmade Jewelry Gifts Share Your Expertise with Your Community

Share Your Expertise with Your Community Creating Color Schemes for Jewelry Making

Creating Color Schemes for Jewelry Making Bronze, Brass, Nickel Silver and Copper Base Metals

Bronze, Brass, Nickel Silver and Copper Base Metals Gemstone Treatments

Gemstone Treatments How Wire is Made

How Wire is Made Beading A-B-C's

Beading A-B-C's How to Set Up Your Workspace

How to Set Up Your Workspace Gem Profile- Diamond

Gem Profile- Diamond Gem Profile- Peridot

Gem Profile- Peridot Gem Profile- Goldstone

Gem Profile- Goldstone Gem Profile- Cryptocrystalline Quartz Introduction

Gem Profile- Cryptocrystalline Quartz Introduction Gem Profile- Banded Agate and Brecciated Agate

Gem Profile- Banded Agate and Brecciated Agate Gem Profile- Emerald

Gem Profile- Emerald Gem Profile- Titanite or Sphene

Gem Profile- Titanite or Sphene Gem Profile- Morganite

Gem Profile- Morganite Gem Profile- Desert Rose

Gem Profile- Desert Rose Gem Profile- Iolite

Gem Profile- Iolite Gem Profile- Zultanite

Gem Profile- Zultanite Gem Profile- Maw Sit Sit

Gem Profile- Maw Sit Sit Gem Profile- Tanzanite

Gem Profile- Tanzanite Gem Profile- Aquamarine

Gem Profile- Aquamarine Gem Profile- Turquoise

Gem Profile- Turquoise Gem Profile- Turquoise Types

Gem Profile- Turquoise Types Gem Profile- What's Druze

Gem Profile- What's Druze Gem Profile- Basalt

Gem Profile- Basalt Gem Profile- Fordite

Gem Profile- Fordite Gem Profile- Variscite

Gem Profile- Variscite Gem Profile- Pearls

Gem Profile- Pearls Gem Profile- Onyx

Gem Profile- Onyx Gem Profile- Sunstone

Gem Profile- Sunstone Gem Profile- Sonora Sunrise

Gem Profile- Sonora Sunrise Gem Profile- Rhodonite

Gem Profile- Rhodonite Gem Profile- Glass, Crystal and Quartz

Gem Profile- Glass, Crystal and Quartz Gem Profile- Psilomelane

Gem Profile- Psilomelane Gem Profile- Fulgurite

Gem Profile- Fulgurite Gem Profile- Cat's Eye

Gem Profile- Cat's Eye Gem Profile- Carnelian

Gem Profile- Carnelian Gem Profile- Petoskey Stones and Indonesian Fossil Coral

Gem Profile- Petoskey Stones and Indonesian Fossil Coral Gem Profile- Rutilated Quartz

Gem Profile- Rutilated Quartz Gem Profile- Chrysocolla

Gem Profile- Chrysocolla Gem Profile- Jet

Gem Profile- Jet Gem Profile- Chrysoprase

Gem Profile- Chrysoprase Gem Profile- Rhyolite

Gem Profile- Rhyolite Gem Profile- Chalcedony

Gem Profile- Chalcedony Gem Profile- Lepidolite and Sugilite

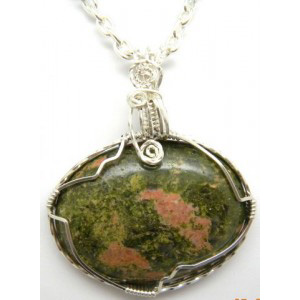

Gem Profile- Lepidolite and Sugilite Gem Profile- Unakite

Gem Profile- Unakite Gem Profile- Cowrie Shells, Conch Shells, and Drilling Shells

Gem Profile- Cowrie Shells, Conch Shells, and Drilling Shells Gem Profile- Mother of Pearl

Gem Profile- Mother of Pearl Gem Profile- Moss Agate and Plume Agate

Gem Profile- Moss Agate and Plume Agate Gem Profile- Thundereggs and Mexican Lace Agate

Gem Profile- Thundereggs and Mexican Lace Agate Gem Profile- Dumortierite

Gem Profile- Dumortierite Gem Profile- Apatite

Gem Profile- Apatite Gem Profile- Blue Topaz

Gem Profile- Blue Topaz Gem Profile- Aragonite

Gem Profile- Aragonite Gem Profile- Zircon and Cubic Zirconia

Gem Profile- Zircon and Cubic Zirconia Gem Profile- Topaz

Gem Profile- Topaz Gem Profile- Howlite

Gem Profile- Howlite Gem Profile- Sodalite

Gem Profile- Sodalite Gem Profile- Magnesite

Gem Profile- Magnesite Gem Profile- Cuprite

Gem Profile- Cuprite Gem Profile- Nuummite

Gem Profile- Nuummite Gem Profile- Bronzite

Gem Profile- Bronzite Gem Profile- Kyanite

Gem Profile- Kyanite Gem Profile- Hematite

Gem Profile- Hematite Gem Profile- Derbyshire Blue John

Gem Profile- Derbyshire Blue John Gem Profile- Eilat Stone

Gem Profile- Eilat Stone Gem Profile- Vesuvianite

Gem Profile- Vesuvianite Gem Profile- Strontium Titanate -Fabulite

Gem Profile- Strontium Titanate -Fabulite Gem Profile- Tourmaline

Gem Profile- Tourmaline Gem Profile- Larimar

Gem Profile- Larimar Gem Profile- Garnet

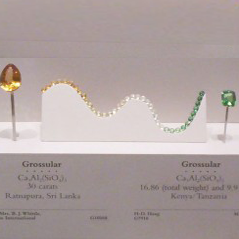

Gem Profile- Garnet Gem Profile- Tsavorite and Green Garnets

Gem Profile- Tsavorite and Green Garnets Gem Profile- Seraphinite

Gem Profile- Seraphinite Gem Profile- Serpentine

Gem Profile- Serpentine Viking Knit Chain and I Cord Chain

Viking Knit Chain and I Cord Chain Copper Roses

Copper Roses How to Make Medical ID Bracelets Special

How to Make Medical ID Bracelets Special Remembering the Fallen

Remembering the Fallen