Purple Turquoise and Turquoise Facts

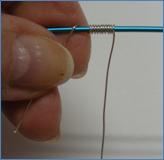

Question:

Hi Dale,

I have recently purchased a purple turquoise pendant drop that I want to use in a necklace. I was assured that the stone was genuine. However, in my research since the purchase, I can find no mention of purple as a natural color of turquoise. Is purple really a natural color of turquoise? Also, I have seen Howlite turquoise advertised. What is Howlite? Thanks so much-I have learned a great deal from the Daily Tip emails!

-Pat in Ringgold, Georgia

Hi Dale,

I have recently purchased a purple turquoise pendant drop that I want to use in a necklace. I was assured that the stone was genuine. However, in my research since the purchase, I can find no mention of purple as a natural color of turquoise. Is purple really a natural color of turquoise? Also, I have seen Howlite turquoise advertised. What is Howlite? Thanks so much-I have learned a great deal from the Daily Tip emails!

-Pat in Ringgold, Georgia

Instructions

Answer:

Hey Pat, I am sorry, but there is no natural purple turquoise. Turquoise is a hydrous phosphate of copper and aluminum, both of which cause the blue to green color. The natural color of turquoise ranges from chalky white to a yellowish green. Of course this leads into "yellow" turquoise, which is a natural material, but an extremely rare form of turquoise. Most of the yellow turquoise on the market today is actually a type of jasper. Remember: If a "rare" product is inexpensive, it's not genuine!

More than likely, what you have is actually a form of reconstituted turquoise, where the dehydrated rock was ground up and mixed with a red dyed resin, forming the purple color in a plastic reinforced product. The term "purple turquoise" has also been used as a synonym for the mineral Sugilite, but turquoise and sugilite are two totally different substances! For more information, we have a few great articles on Turquoise that describes the different treatments used, as well as its amazing journey through history.

Hey Pat, I am sorry, but there is no natural purple turquoise. Turquoise is a hydrous phosphate of copper and aluminum, both of which cause the blue to green color. The natural color of turquoise ranges from chalky white to a yellowish green. Of course this leads into "yellow" turquoise, which is a natural material, but an extremely rare form of turquoise. Most of the yellow turquoise on the market today is actually a type of jasper. Remember: If a "rare" product is inexpensive, it's not genuine!

More than likely, what you have is actually a form of reconstituted turquoise, where the dehydrated rock was ground up and mixed with a red dyed resin, forming the purple color in a plastic reinforced product. The term "purple turquoise" has also been used as a synonym for the mineral Sugilite, but turquoise and sugilite are two totally different substances! For more information, we have a few great articles on Turquoise that describes the different treatments used, as well as its amazing journey through history.

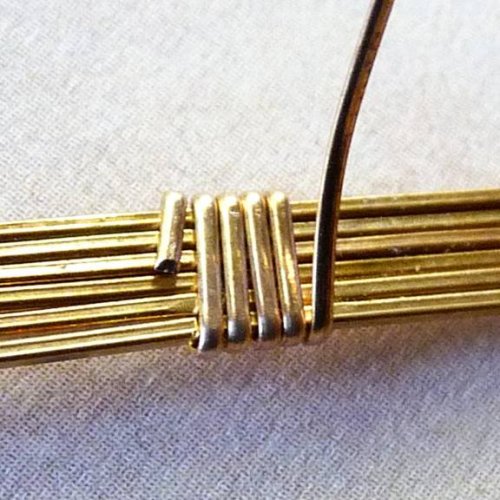

Howlite (the stone pictured for the post) is an amazing mineral because it is abundant and it takes a dye really well. With a Mohs hardness of 3.5, stone carvers enjoy working with Howlite, producing all forms of small to large charms and statues. Because Howlite has black veining, it is often dyed to resemble turquoise and in its natural color it is most often misrepresented as "white turquoise" or "white buffalo turquoise". (Yes, when natural turquoise is dehydrated, it is a soft, chalky, white material, but unless it is stabilized with resin, it is impossible to work with.) The dye process is what needs to be watched; some factories will use a mixture of dye, sugar, and heat, resulting in a temporary dye that will come off in just water or on the skin. Click here to read more on howlite.

The following is just a little story from my experiences while rockhounding in the American Southwest. My husband and I met a prospector who had an unusual way of stabilizing the turquoise he dug. He collected old paint cans, loaded them halfway with dehydrated turquoise pieces, and then added a plastic resin. Then he placed the cans on old picnic tables in the desert behind his home (via ann at dress head tech). The natural heat from the sun added to the curing resin heat, and when the paint can tops blew off, the stabilized turquoise was ready. No kidding - it worked for him! (Don't try this at home!)

The following is just a little story from my experiences while rockhounding in the American Southwest. My husband and I met a prospector who had an unusual way of stabilizing the turquoise he dug. He collected old paint cans, loaded them halfway with dehydrated turquoise pieces, and then added a plastic resin. Then he placed the cans on old picnic tables in the desert behind his home (via ann at dress head tech). The natural heat from the sun added to the curing resin heat, and when the paint can tops blew off, the stabilized turquoise was ready. No kidding - it worked for him! (Don't try this at home!)

Note:

At the time of this article Wirejewelry is offering some Yellow Turquoise beads that are actually the jasper or serpentine that has been dyed a rich yellow color.

Our Designer One of a Kind Cabochons have a variety of beautiful Turquoise.

At the time of this article Wirejewelry is offering some Yellow Turquoise beads that are actually the jasper or serpentine that has been dyed a rich yellow color.

Our Designer One of a Kind Cabochons have a variety of beautiful Turquoise.

Materials

African Turquoise 10x14mm Oval Beads - 8 Inch Strand

A1-739

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $11.07

- Gold Club Price: $8.30

Sterling Silver Chain w/Bezelled Turquoise 12 to 15mm - 1 Foot

C8-210U

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $23.97

- Gold Club Price: $17.98

Yellow Turquoise 16mm Round Beads - 8 Inch Strand

A1-496

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $11.68

- Gold Club Price: $8.76

Designer One of a kind Cabochons in Turquoise

Tools

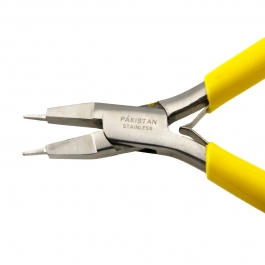

Ultimate wire-pliers Set

G15-20

- G15-20

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $99.95

- Gold Club Price: $74.96

- Category: General Education

- Technique(s): General Education

Make a Finished Ribbon Necklace

Make a Finished Ribbon Necklace Sell or Display Valued Stones

Sell or Display Valued Stones Cleaning with Baking Soda

Cleaning with Baking Soda Irradiated Quartz Necklace

Irradiated Quartz Necklace Removing Rust Without Damaging Tools

Removing Rust Without Damaging Tools Wire Jewelry to Make as You Sell

Wire Jewelry to Make as You Sell All About Soft Wire

All About Soft Wire Chain Lavaliere

Chain Lavaliere Wire Metal Substitutions

Wire Metal Substitutions Glue for Finishing Cords

Glue for Finishing Cords My Fingers Hurt

My Fingers Hurt Taming the Wild Wire Bundle

Taming the Wild Wire Bundle Making Matching Freeform Earrings

Making Matching Freeform Earrings What is My Wire's Circumference

What is My Wire's Circumference Testing True Ivory

Testing True Ivory Is My Coral Real

Is My Coral Real Wrapping Tiny Cabs

Wrapping Tiny Cabs Finished Leather Cord

Finished Leather Cord Prevent Scratches on Cabochons

Prevent Scratches on Cabochons Crystal Wave Ring Finishing Tips

Crystal Wave Ring Finishing Tips Purity and Sensitivity with Argentium Silver

Purity and Sensitivity with Argentium Silver Wrapping Coins for Jewelry

Wrapping Coins for Jewelry Wrapping a Large Pearl Ring

Wrapping a Large Pearl Ring Perfect Chain for Wire Jewelry

Perfect Chain for Wire Jewelry How Do I Keep Square Wire From Twisting When Wrapping

How Do I Keep Square Wire From Twisting When Wrapping Wire Temper by Number

Wire Temper by Number Will Liver of Sulfur Harm Lampwork Beads

Will Liver of Sulfur Harm Lampwork Beads Forging Copper Wire

Forging Copper Wire Insurance for Art and Craft Shows

Insurance for Art and Craft Shows Wire Temper for Ear Pins

Wire Temper for Ear Pins Wire Size for Wrapping a Cabochon

Wire Size for Wrapping a Cabochon Can I Use the Copper Wire From Electrical Wire

Can I Use the Copper Wire From Electrical Wire Wire Jewelry for a Home Party

Wire Jewelry for a Home Party What is a Juried Craft Show

What is a Juried Craft Show Wire Wrap Ideas for Beginners

Wire Wrap Ideas for Beginners What is the Difference Between Different Plated Jewelry

What is the Difference Between Different Plated Jewelry Wrapping Pearls onto a Hair Grip

Wrapping Pearls onto a Hair Grip Formulas for Pricing Jewelry and Selling Jewelry- Boutique Markup

Formulas for Pricing Jewelry and Selling Jewelry- Boutique Markup White Gold in Wire Jewelry

White Gold in Wire Jewelry What is White Gold

What is White Gold How to Clean and Repair Ivory Jewelry

How to Clean and Repair Ivory Jewelry Twisted Wire Tips

Twisted Wire Tips Forging Wire

Forging Wire Gemstone Ratings Explained

Gemstone Ratings Explained Finishing a Cabochon Frame

Finishing a Cabochon Frame Making Tiny Headpins Larger

Making Tiny Headpins Larger Sorting and Using Scrap Wire

Sorting and Using Scrap Wire Silver and Nickel in Ear Wires

Silver and Nickel in Ear Wires Options for Practice Wire

Options for Practice Wire Help with Pricing Wire Jewelry

Help with Pricing Wire Jewelry Flush Cutters vs. Side Cutters

Flush Cutters vs. Side Cutters Wrapping Small Gemstones

Wrapping Small Gemstones Argentium Silver Care

Argentium Silver Care Proper Care of Pearls and Opals

Proper Care of Pearls and Opals Wire Wrapping Stones with No Holes

Wire Wrapping Stones with No Holes Cup Bur Sizes for Wire Gauges

Cup Bur Sizes for Wire Gauges Learning How to Sell Jewelry

Learning How to Sell Jewelry Seashell Jewelry with an Underwater Finish

Seashell Jewelry with an Underwater Finish Anodized Aluminum and Chipping

Anodized Aluminum and Chipping Rock Tumbling 101

Rock Tumbling 101 Home Jewelry Show Inventory

Home Jewelry Show Inventory Wire Wrapping Term - To Show

Wire Wrapping Term - To Show Lindstrom or Swanstrom Pliers

Lindstrom or Swanstrom Pliers What is Niobium Wire

What is Niobium Wire Can Lindstrom Cutters be Repaired

Can Lindstrom Cutters be Repaired Trillion Ring Designs

Trillion Ring Designs Copper Hat Pins

Copper Hat Pins Making Wire Jewelry from Patterns, and Copyright

Making Wire Jewelry from Patterns, and Copyright Removing Nicks and Scratches

Removing Nicks and Scratches Pricing Jewelry Made with Gold Wire

Pricing Jewelry Made with Gold Wire How to Polish Apache Tears

How to Polish Apache Tears Which Wire Should I Use to Make My First Bracelet

Which Wire Should I Use to Make My First Bracelet Working with Small Jump Rings

Working with Small Jump Rings Repairing a Bead Wire

Repairing a Bead Wire Mixing Sterling Silver and Argentium

Mixing Sterling Silver and Argentium Wrapping a Pear-Shaped Cut Stone

Wrapping a Pear-Shaped Cut Stone Wrapping a Rectangle Cab

Wrapping a Rectangle Cab Oxidizing Sterling Silver

Oxidizing Sterling Silver What to Use in Jewelry Tumbler

What to Use in Jewelry Tumbler Wire Gauge for Hoop Earrings

Wire Gauge for Hoop Earrings Using a Ring Mandrel

Using a Ring Mandrel Protecting Copper from Tarnishing

Protecting Copper from Tarnishing Resizing a Shank with Wire

Resizing a Shank with Wire Setting Stones in Jewelry

Setting Stones in Jewelry Bending Pattern Wire

Bending Pattern Wire Wire Wrapping Thick Stones with Little Girdles

Wire Wrapping Thick Stones with Little Girdles Enlarging Holes in Gemstones

Enlarging Holes in Gemstones Best Way to Make Jump Rings

Best Way to Make Jump Rings Removing Marker from Jewelry Wire

Removing Marker from Jewelry Wire Wire Size for Earrings

Wire Size for Earrings Where to Place Wraps on Free-Form Pieces

Where to Place Wraps on Free-Form Pieces How Do I Find Shows in My Area

How Do I Find Shows in My Area Master Wire Gauges with Draw Plates and Draw Plate Tips

Master Wire Gauges with Draw Plates and Draw Plate Tips Holding Bundles of Wire Straight

Holding Bundles of Wire Straight Twisting Wire Evenly

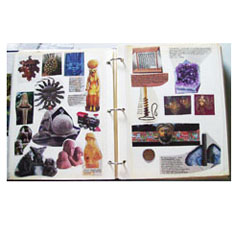

Twisting Wire Evenly Why Use a Designer's Notebook

Why Use a Designer's Notebook Embossing Hammers and Wire Texture

Embossing Hammers and Wire Texture Making a Bracelet with Prong Set Stones

Making a Bracelet with Prong Set Stones What are Cold Connections

What are Cold Connections Supply Lists for Wire Jewelry DVDs

Supply Lists for Wire Jewelry DVDs Patina Silver-Plated Wire

Patina Silver-Plated Wire Prevent and Remove Verdigris

Prevent and Remove Verdigris Is Work-Hardened Half Hard Wire, Hard Enough

Is Work-Hardened Half Hard Wire, Hard Enough What Are Some Better Selling Beginner Items

What Are Some Better Selling Beginner Items Removing Glue from Dichroic Glass

Removing Glue from Dichroic Glass One Jump Ring Gauge to Rule Them All

One Jump Ring Gauge to Rule Them All Adjusting Jewelry Prices with the Metal Market

Adjusting Jewelry Prices with the Metal Market Making Wire Jewelry for Men

Making Wire Jewelry for Men Determining Carat Weight

Determining Carat Weight Building on Snake Style Chain

Building on Snake Style Chain How to Keep Stainless Shot Free of Residue

How to Keep Stainless Shot Free of Residue Crochet Wire Designs

Crochet Wire Designs Heating Porcelain Cameos

Heating Porcelain Cameos Storing Your Jewelry

Storing Your Jewelry How to Win Awards for Jewelry Design

How to Win Awards for Jewelry Design Wrapping Small Stones

Wrapping Small Stones Tips for Working with 18G Wire

Tips for Working with 18G Wire Organizing Beads for Easy Jewelry Making

Organizing Beads for Easy Jewelry Making What Is a Cabochon

What Is a Cabochon The Best Wire Temper for Rings

The Best Wire Temper for Rings Making Wire Jewelry with Crystals

Making Wire Jewelry with Crystals When to Use Flat Nose Prong Making Pliers

When to Use Flat Nose Prong Making Pliers Measuring for a Bracelet

Measuring for a Bracelet What Chain Sizes Are Best

What Chain Sizes Are Best Pharaoh Ring Wires

Pharaoh Ring Wires How to Wrap a Broken Cabochon

How to Wrap a Broken Cabochon How Do You Use Memory Wire

How Do You Use Memory Wire Organizing Jewelry Wire

Organizing Jewelry Wire Starting Position of Wrap for Ring Shanks

Starting Position of Wrap for Ring Shanks Faceted Gemstone Terms

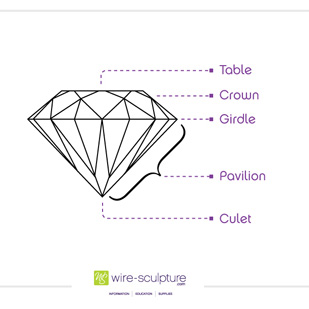

Faceted Gemstone Terms What is the Average Size for Bracelets

What is the Average Size for Bracelets Red Rouge

Red Rouge Rosary Links and Wire Temper

Rosary Links and Wire Temper Jewelers' Saws and Jump Rings

Jewelers' Saws and Jump Rings Wrapping Cabochons

Wrapping Cabochons What is Rolled Gold Wire

What is Rolled Gold Wire Traditional Gemstone Pendant Wrapping

Traditional Gemstone Pendant Wrapping Flattening Wire with Hammers

Flattening Wire with Hammers Foolproof Jump Ring Closures

Foolproof Jump Ring Closures How to Use a Wire Gauge

How to Use a Wire Gauge Jazz up Your Jewelry

Jazz up Your Jewelry Optivisor Distance and Magnification

Optivisor Distance and Magnification Photographing Your Wire Jewelry

Photographing Your Wire Jewelry Prong-Setting Ideas for a Cut Stone

Prong-Setting Ideas for a Cut Stone Sterling Silver and Fresh Water Pearls

Sterling Silver and Fresh Water Pearls Ultimate Jewelry Tool Shopping List

Ultimate Jewelry Tool Shopping List Wire Jewelry Tool Care

Wire Jewelry Tool Care How to Set Stones into Earring Snapsets

How to Set Stones into Earring Snapsets